Translate this page into:

Multi-layered masks to combat COVID-19

-

Received: ,

This is an open access journal, and articles are distributed under the terms of the Creative Commons Attribution-NonCommercial-ShareAlike 4.0 License, which allows others to remix, tweak, and build upon the work non-commercially, as long as appropriate credit is given and the new creations are licensed under the identical terms.

This article was originally published by Wolters Kluwer - Medknow and was migrated to Scientific Scholar after the change of Publisher.

On June 5, 2020, the World Health Organization (WHO) has issued interim guidelines for the use of multi-layered textile fabrics as masks to combat COVID-191. The non-medical or non-surgical masks specifically designed for the general public or low-risk individuals can be made up of a variety of arrangements of fabrics in different layering sequences. Partitioning the mask in three distinct layers, the WHO recommended that the innermost layer should be made up of hydrophilic fibres, whereas the middle and outer layers need deployment of hydrophobic fibres. Although the precise design principles of the multi-layered masks to limit the spread of COVID-19 have not been clearly documented, there are innumerable combinations of materials and fabrics that yield a large variability in terms of filtration and breathability.

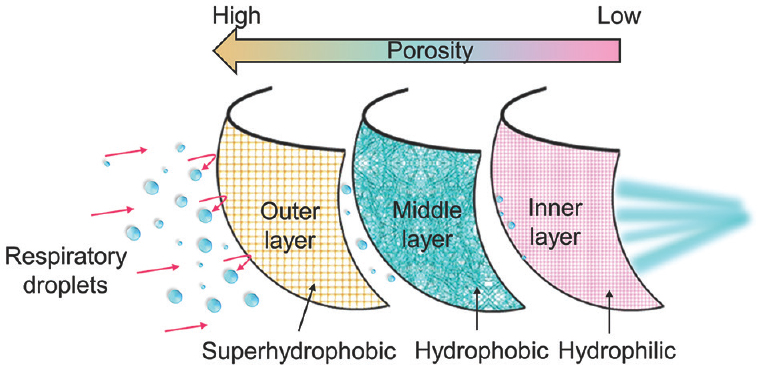

The conventional design principles of facemasks rely on a fact that the particle smaller than the pore dimensions is removed from fluid via inertia, impaction, diffusion and electrostatic attraction. Notably, the principles of inertia and impaction may not be applicable for the free virions or droplet nuclei as the diffusion phenomenon is dominant at this length scale2. The layers of the mask can be designed by virtue of graded porosity and hydrophobicity - the outermost layer has the highest porosity and extreme water repellency than the innermost layer (Figure). In other words, there should be a progressive reduction of pore dimensions and hydrophobic behaviour from the outer to the innermost layer. Specifically, the decrease in pore dimensions can assist in reducing the pressure drop across the mask3. To attain such a design criterion, a spunbonded non-woven or a loosely woven fabric made up of highly hydrophobic synthetic fibres can be used as an outer layer followed by a melt-blown non-woven in the middle layer. The porous outer layer can act as a shield against the respiratory droplets, and it should be engineered in a manner that there is a minimum contact area between liquid and solid surface enhancing the water repellency4.

- Multi-layered masks with graded porosity and hydrophobicity.

Normal speaking creates splashing of respiratory droplets with a broad size distribution (0.1-1000 μm)5. The probability that a 50 μm diameter droplet consists of at least one virion before dehydration is as high as 37 per cent6. For such large-sized droplets, the mask should not just act as a ‘catchment area', but these droplets should be allowed to roll-off on the surface of the outer layer. Although the hydrophobicity of porous woven/non-woven textiles present in the outer layers is reasonably high due to the Cassie-Baxter effect7, yet it does not improvise the droplet to roll-off. A metastable air-water-solid composite interface is generally formed on the fabric surface as the air is being trapped underneath the asperities emanating from fibre-fibre or yarn-yarn contacts8. In this scenario, the droplet may not roll-off easily on the fabric surface but rather clings to it, similar to a ‘rose-petal’ effect9. The pinning effect of a droplet on the surface of textile can become a source of self-contamination as the manipulation of a facemask can occur using contaminated hands1. Therefore, the hydrophobic outer layer of the non-medical mask may not be sufficient in controlling the spread of the infection as the fluid penetration is inevitable10. To a large extent, the superhydrophobic effect or extreme water repellency of the outer layer can address the issue of self-contamination.

Self-cleaning established via a superhydrophobic effect in the outer layer is highly desirable that allows the droplet to form a spherical shape and roll-off when tilted by a few degrees11. Superhydrophobicity is manifested via low surface energy and hierarchical roughness11. Recent advances in the field recommended the use of coating as one of the ways to reduce the surface energy of the mask for superhydrophobic effect. For instance, the dual-mode laser-induced forward transfer method was adapted to deposit a few layers of graphene that resulted in lowering the surface energy of the melt-blown mask for superhydrophobic effect12. Although the approach is facile and scalable for catering to the demands of the general population, but the coating of masks can block the pores and compromise with their breathability1. Further, it is still naive to advocate the use of nanomaterials in the masks based on their ambiguous safety profile and health impacts. Rather, the efforts should be directed towards the interplay of fibre and structural characteristics or applying the hydrophobic finishes during the production of masks.

Finally, the innermost layer of the mask is a key component in controlling the droplet splashed out by the wearer. A tightly woven cotton fabric in the innermost layer can attain a filtration efficiency of 80 per cent for particle sizes of <300 nm13. However, a trade-off is required to be maintained between a tightly woven fabric and breathability. Another important consideration is the particle size distribution that is employed for the testing of masks. Intermediate particle size (0.04-0.4 μm), also known as the ‘most penetrating particle size’ (MPPS), is the most difficult to be captured by the masks14. The MPPS is influenced by several factors, including filter face velocity, porosity, fibre diameter, airflow, fibre charge density and particle size distribution151617. For the electret mask, the MPPS shifts towards 40-50 nm18 and can overestimate the filtration efficiency, which can be easily overcome using charge-neutralized aerosols17. Thus, it is of paramount importance to determine the filtration efficiency with the aerosols at the MPPS range.

Indisputably, the judicious design of the multi-layered mask can act as an armour against the spread of COVID-19, but it also presents more challenges to the environment as there would be a surge in demand for the use of plastic products19. One of the ways to address this issue is to reuse these multi-layered masks, which can be realized by applying steam treatment under controlled humid conditions20. Careful temperature conditions are still required to be in place, particularly for the low melting polymers, as the structural integrity of the mask can easily be compromised12. Though the multi-layered masks are one of the preventive measures, but social distancing, hand hygiene, and the other guidelines recommended by the WHO form a comprehensive package to control the spread of the infection. With the gradual exit from the lockdown, it becomes imperative that one of the key government strategies across the globe should focus on the suitable universal masking solutions for the general public that limits the spread of the virus.

Financial support & sponsorship: Financial support was provided by the Department of Science and Technology under project no. MTR/2019/000098.

Conflicts of Interest: None.

References

- Advice on the use of masks in the context of COVID-19. Available from: https://wwwwhoint/publications/i/item/advice-on-the-use-of-masks-in-the-community-during-home-care-and-in-healthcare-settings-in-the-context-of-the-novel-coronavirus-(2019-ncov)-outbreak

- Filtration efficiencies of nanoscale aerosol by cloth mask materials used to slow the spread of SARS-CoV-2. ACS Nano. 2020;14:9188-200.

- [Google Scholar]

- Prediction of pressure drop in non-woven filter media using a hagen-poiseuille model. Tribol Trans. 2000;43:251-6.

- [Google Scholar]

- Design parameters for a robust superhydrophobic electrospun nonwoven mat. Langmuir. 2012;28:3285-9.

- [Google Scholar]

- The airborne lifetime of small speech droplets and their potential importance in SARS-CoV-2 transmission. Proc Natl Acad Sci. 2020;117:11875-7.

- [Google Scholar]

- Design of a superhydrophobic surface using woven structures. Langmuir. 2007;23:6004-10.

- [Google Scholar]

- Petal effect: A superhydrophobic state with high adhesive force. Langmuir. 2008;24:4114-9.

- [Google Scholar]

- Resistance to synthetic blood penetration of National Institute for Occupational Safety and Health-approved N95 filtering facepiece respirators and surgical N95 respirators. Am J Infect Control. 2015;43:1190-6.

- [Google Scholar]

- Reusable and recyclable graphene masks with outstanding superhydrophobic and photothermal performances. ACS Nano. 2020;14:6213-21.

- [Google Scholar]

- Aerosol filtration efficiency of common fabrics used in respiratory cloth masks. ACS Nano. 2020;14:6339-47.

- [Google Scholar]

- Handbook of nonwoven filter media. Oxford: Elsevier; 2007.

- On the minimum efficiency and the most penetrating particle size for fibrous filters. J Air Pollut Control Assoc. 1980;30:377-81.

- [Google Scholar]

- Theoretical study of aerosol filtration by fibrous filters. Aerosol Sci Technol. 1982;1:147-61.

- [Google Scholar]

- What does respirator certification tell us about filtration of ultrafine particles? J Occup Environ Hyg. 2008;5:286-95.

- [Google Scholar]

- Manikin-based performance evaluation of N95 filtering-facepiece respirators challenged with nanoparticles. Ann Occup Hyg. 2006;50:259-69.

- [Google Scholar]

- Minifmising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew Sustain Energy Rev. 2020;127:109883.

- [Google Scholar]

- Can N95 respirators be reused after disinfection? How many times. ACS Nano. 2020;14:6348-56.

- [Google Scholar]